FHS Students Visit SCC in Milford

September 19, 2018, Mr. Scott and ten FHS students had the privilege to tour Southwest Community College in Milford for their annual Career Construction Days. The group consisted of FHS juniors and seniors. Students had to sign up in advance online and request three areas of study that are offered at the college in Milford.

The day started off with Fairbury students and many other students from area schools all in a big gymnasium for an opening session where they listened to a guest speaker. They were all given a bag that contained information about the college. Next they were divided into roughly 28 different groups each containing a tour guide. There were teachers, students and volunteers there guiding the students from building to building.

Some of the areas of study that FHS students went to were Computer Aided Drafting, Auto body Repair, Construction, Masonry, Electrical and HVAC, Diesel Mechanics, Heavy Equipment Operation and Automotive Service and Maintenance.

It was a nice day and the weather was great. It was a rewarding visit and many found that the two year programs of study are what they really want today. Two year programs can land students great jobs. We even got to see a couple of graduates from last year on campus. Those students were nice to show us around and answer questions the younger students had.

STS Class Builds MouseTrap Vehicles

Students in Mr. Scott’s STS (Skilled Technical Sciences) class are busy making mousetrap vehicles. Students were given a standard Victor mouse trap and they have to design, build and test a vehicle that can go the farthest distance. This will test their problem solving abilities as well as working together with other classmates to accomplish their goal. Students could use about anything for materials such as wood, metal or plastics. They are realizing friction and weight are big factors. Students are also finding out that sometimes their first attempt is not always successful which is really how it is in making anything. Sometimes products must be redesigned and tested all over again. Just think how many times Edison attempted to make his light bulb idea work. Pictured with their cars are Leland Abbott, Juan Montes Lemus and Ashton Blobaum.

Jefferson County Spelling Bee

Students and Teachers Attend Digital Citizenship Symposium

TeamMates In October – Strengths Day

TeamMates of Fairbury is excited to once again be recognized as a Strengths chapter!

What does this mean?

“Through the Gallup strengths partnership, mentors and mentees can better understand and maximize the unique human potential that each person brings to their roles in school and life.”

When?

We are holding trainings throughout the day on Monday, October 8th. For a Mentor Renewal “Lunch n’ Learn”, meet at the Administration building at 12 pm. Mentees should plan to stay after school to take the strengths survey. And Mentors, please join us at 5:15 for Strengths Training.

If you are unable to attend but still want to be able to learn more about yourself and your TeamMate through Strengths, we can find a time that works best for you. Please contact me at tebke@fairburyjeffs.org to RSVP or for more information.

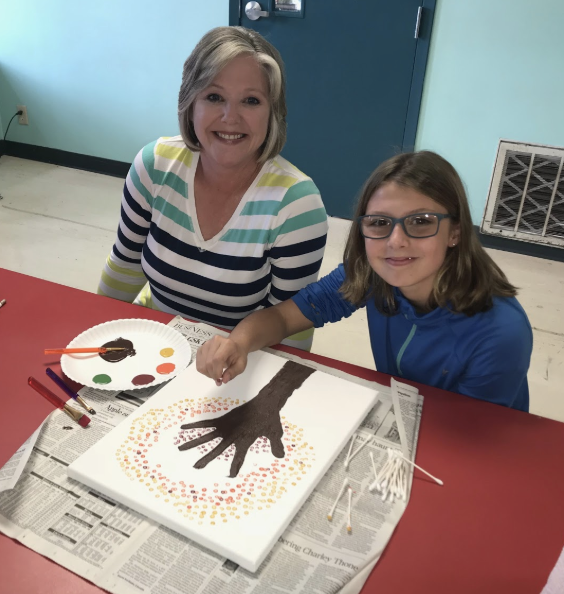

Activity of the Month – Fall Inspired Painting

Tuesday, October 30th – 3:45 pm at Jefferson

This simple project requires autumn colored paints, a pencil for tracing your hand, a canvas or thick piece of paper, and Q-Tips to dab leaves onto the tree. Simple, beautiful, and sentimental. Thanks to our new match, Tonya and Micah for going outside the box with their weekly match activity! For more Fall related craft ideas, follow our Fall Craft Board on the Fairbury TeamMates Pinterest page.

Happy Mentoring and Happy Fall!

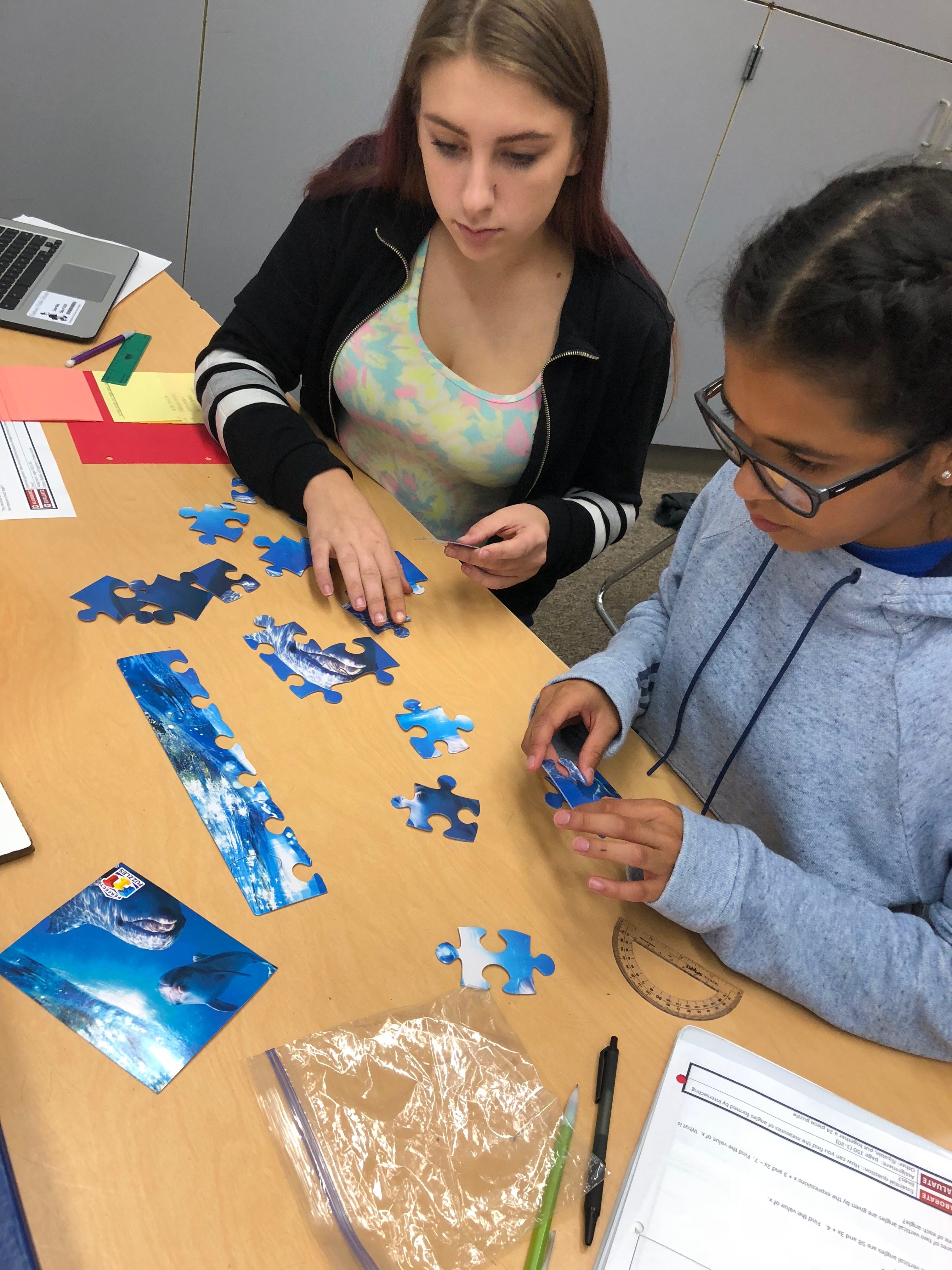

Geometry Students Developing Proofs

When you put a puzzle together, how do you approach the first few pieces? Most people, geometry students included, begin with the edges of the puzzle. Then you can start to put the whole picture together inside.

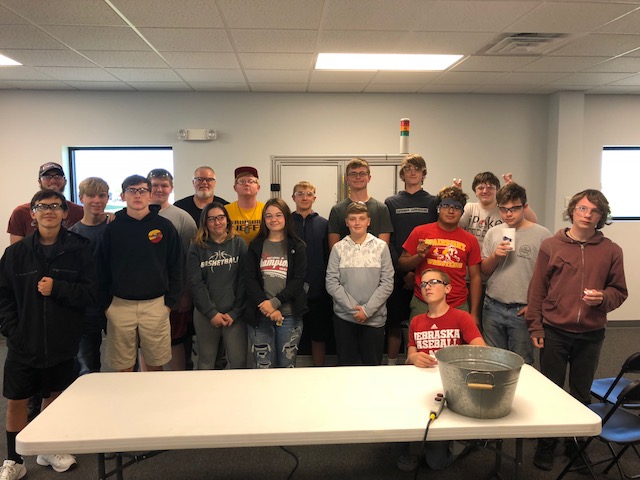

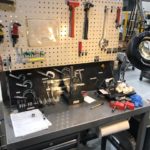

STS Students Tour MetalQuest Unlimited

Sixteen students in Mr. Scott’s Skilled Technical Science class got the opportunity to tour Metal Quest Unlimited in Hebron Nebraska on 9-26-18.

The History of MetalQuest

MetalQuest Unlimited started on Jan. 1, 1996 in a man’s garage with one metal lathe and a vision for the future and a passion for innovation. The business began with no guarantee of work, and greatly in debt like most start-up companies.

In the first 6 months of operation, MetalQuest added a second machine and added the first employee. It took about three years to see the investment pay off and the rest is history. MetalQuest calls Hebron, Nebraska its home now. MetalQuest believes in hard work, determination and teamwork. These are still the building blocks of the MetalQuest philosophy.

MetalQuest manufactures precision machined component parts with an emphasis in product line and part family manufacturing. In other words, they may take a part they buy from one company like a foundry company and turn it into a part that they machine and perform some industrial processes on.

FHS students were divided up into two groups and they got to see technology all over the plant with robots that grind parts, polish parts, measure parts, box parts and even store parts. The floor even had a wire in the concrete for a robotic forklift to follow to store and retrieve parts. That robotic lift could not deviate from its path making it safer for employees in the plant.

For all the math teachers at FHS, mathematics is a must with just about all the employees despite what many may think. The use of Trigonometry and precision measuring is a must. There were many tools in the factory that have to be used daily to measure close tolerances such as calipers and micrometers. Students saw the connection between what they are learning at FHS and how that can be use those skills in a job situation. Blueprint reading was also an important skill. MetalQuest uses SolidWorks as their main Software program for the development of their drawings. MetalQuest just ordered a new 3D printer to do part modeling so they can see and hold the parts before they are manufactured. Just one machine in the factory can cost as much as $600,000 dollars each so production down time is not a good thing. They try to keep all machines running all the time. They run two shifts of employees with a $4.00 dollar jump for night shift workers. Weekend workers can earn time and a half.

Just so you know, MetalQuest to name a few makes hydraulic valves for John Deere, silencer parts for guns, valves for hydraulic control systems and many other parts.

I want to thank Dave Sammartano, the training coordinator at MetalQuest and the rest of the staff for letting us come over and tour the facility. It was a rewarding time well spent. The students had a great time.